The step screen is successfully used for the solid-liquid separation operations, as it is a valuable system for the mechanical separation of grits, detritus and floating media from liquids. Its typical field of usage is in the wastewater treatment plants, where an effective primary screening is the best way to keep in an efficient mood all the following processes.

How do step screen work ?

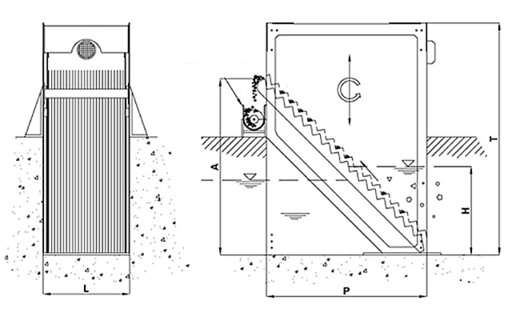

This machine is made by a series of laminas with a step design whose spacing determines the free passage dimension, and consequently the caliber of the removed debris.

The operating principle is quite easy: the filtering entity is divided into two independent and interpenetrating blocks, one mobile and the other steady, whose relative movement produces a steady going of the filtered media through the discharge, keeping the filtering spaces always clean and free. The shape of the bars is such to involve the filtered media itself in the screening process, bringing the sieving over the limits given by the spaces between the laminas. This because the deposit of the solid particles on the screening bed can be used to improve the percentage of removed floating media. The removal of these is gradual and steady. When choosing the bar free space take in the right account the wide filtering surface that allows to work with low fluid speed through the grid, this reduces the loss of head of the fluid.

Installation and Maintenance

The modular structure of the screen makes possible to install it even in existing channels and works, without the need to modify the concrete works. A proper way to complete the system is to place a conveyor belt under the discharge to improve the conveying and stocking of the removed material, or even a better solution is to place a screw conveyor with compacting and dewatering zone. Our screen is simple and strong built, meeting service managers and maintenance workers needs.

During the engineering phase we avoid the presence of useless mechanical complications, in the machine there aren’t complicated remand, there are no chains nor deformable quadrilaterals.

The main characteristic of this machine is that all the transmission systems, included bearings, shafts and couplings are high above the water level and out of the concrete channel. In this way we avoid that the main mechanical components of the machine can be touched by the water, and we improve the accessibility to the machine for the maintenance, whose need is kept under control by the huge sizing of the components.

Material and manufacturing

The presence of an all-around cover, designed to protect the machine until the channel edge, protect the moving parts from the weather, and it is a protection system for the safety of the plant personnel as well. Usually our step screens are entirely made by stainless steel according to AISI 304 or AISI 316, even in low carbon version, and supplied with material certificates, but we can consider to build them with other materials if it is required by the installation needs.